JAWBONE INDUSTRIAL CO., LTD. is a leading manufacturer, supplier and exporter of Injection Moulding Products, with a factory in Taiwan. We supply and export consistently high class products and continually improve upon the manufacturing processes and work environment through total employee involvement and strict adherence to fair business ethics. We have gained several patents in the field. Our sincerity and hard work has helped us to match our quality with international standards. If you are interested in any styles of our products, please feel free to contact us.

Injection Moulding Products

Meridian Meter

SP-001

Provide surface finish such as plating, painting, water transfer printing, fabric wrapping, printing, laser engraving, etc.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: PC+ABS. All kinds of engineering plastic are available based on customers’ demands.

Color: Golden, sliver and white colors. Colors can be customized upon request.

Surface Finish: Texture. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Equipment & Capacities

Bronzing machine

Automated dispensing machine

Ultrasonic welding machine

UV laser engraving machine

Single/double/ three-color pad printing machine

Semi-automatic silk screen printing machine

Automated painting line

Assembly line

Secondary Processing

Drilling, tapping, heat staking, ultrasonic welding, dispensing, laser cutting, CNC engraving, etc.

Surface Finishing

Painting, printing, in-mold decoration, hot bronzing, electroplating, laser engraving, anode, powder coating, etc.

Assembly and Testing

Semi-finished and finished assembly, and testing.

Packing and Shipping

Asset Label (Tracker)

AT-004

Includes various assembly process such as tightening up screws, heat-staking inserts, glue dispensing, foam tape attaching, ultrasonic welding, etc.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: PETG. All kinds of engineering plastic are available based on customers’ demands.

Color: White. Colors can be customized upon request.

Surface Finish: Special texture. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

RFQ - Product-related information

To save your time in RFQ, we would like you to provide the following information:

Product Files: 3D file (.stp) and 2D drawing. Samples would be fine.

Materials and Specifications: Please advise the color/material of the product. If it is not decided yet, we can recommend materials per your product requirements.

Surface Treatment and Post-processing Requirements: Secondary processes, such as glossy surface, texture, painting, printing, etc.

Other Product Information: Product application, finished/semi-finished assembly needs, special dimension tolerances, etc.

Quote Quantity: Order quantity or annual quantity.

Place of Delivery: Detailed delivery address or port.

Shipping Methods: If the product needs to be exported, please indicate the shipping method, we will quote the shipping fee separately. Generally, our quotation is Ex-Works (EXW) price.

Packaging Methods: General bulk or special packaging needs.

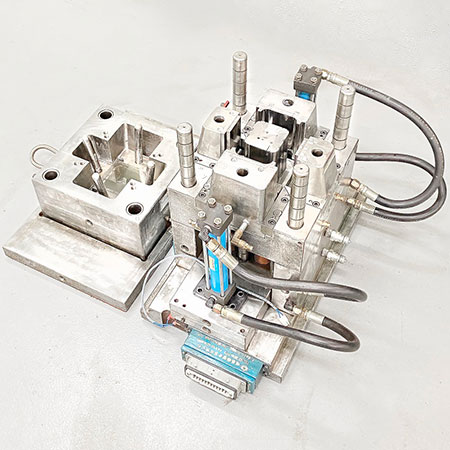

Surveillance Camera Top Mold

PM-002

RIM mold with hot runner design.

Development: Mold design and mold injection are according to customers’ CAD; offer free mold trial samples.

Material: PC+ABS. All kinds of engineering plastic are available based on customers’ demands.

Surface Finish: Polishing. Both texture and polishing are available upon request.

Color: Grey and orange. Colors can be customized upon request.

Mold Base Steel: Select the most suitable P5 steel according to demands.

Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Demolding Mechanism: Provide solutions. With precision hydraulic cylinder mechanism actuation.

Gate Type: Design the best runner system according to product demands.

Cooling System: Design the best conformal cooling channels according to structure of the product.

Ejection System: Design the best ejection method according to structure of the product.

Jawbone provides customer with the best choice for precision film materials.

Jawbone provides customers with the best products and services with our core technologies, equipment and capacities.

Core Technologies

Custom mold design and build

Continuous thin film coating

Continuous thin film printing

Stamping/die-cutting

Thin film lamination, etc.

Equipment & Capacities

Roll to roll thin film coating machines

Roll to roll automatic printing machines

C-type high-precision press punch

Thin film laminating machine with alignment function

Automated optical inspection (AOI)

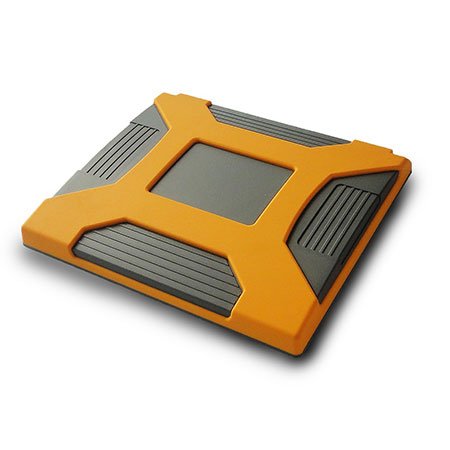

Outdoor Ultrasonic Device

DSPM-002

This product is specially used in outdoor places like farms and ranches. It is with anti-collision and water-repellent features which is able to withstand trucks or other heavy things running over.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: Plastic PC + PBT/TPE. All kinds of engineering plastic are available based on customers’ demands.

Color: Orange and grey. Colors can be customized upon request.

Surface Finish: Textured. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Precision Craft from Design to Processing

With CAE analysis, we reduce development risk.

Jawbone has capability of precision mold built and precision processing equipment. Through mold flow analysis and design review by skilled engineers before making the mold, we find the best solution for product molding. Also, Jawbone strengthens the structure and quality of mold to reduce the need of mold modification and to minimize development risk. We provide customers with timely and cost-effective mold development services.

Our policy is to achieve customers' satisfaction both by providing them with high level

Injection Moulding Products

and services that meet or exceed their expectation. It is our force to manufacture products to suit the exact requirement of our client ranging from small industries to manufacturing units.Injection Moulding Products Manufacturers, Suppliers-JAWBONE INDUSTRIAL CO., LTD.

Established in Taiwan, we, JAWBONE INDUSTRIAL CO., LTD., are a leading Manufacturer, Supplier and exporter of Injection Moulding Products, our technique and products include Plastic Injection Molding, Plastic Overmolding, 2 Shot Plastic Molding, Plastic Insert Molding, Plastic Mold, Plastic Mold Design, Plastic Molding Products, Assembly And Testing, Mechanical Design, and Secondary Processes, etc.. These are manufactured using the best quality raw materials at our ultramodern infrastructure facility. Our products guarantee optimum satisfaction of the end users.

We give you wide range of Injection Moulding Products as per your requirements; our material is made up of high quality material that is quality tested. Customers can avail this service from us in a given time at affordable rates. In addition to manufacturing these offered products in standard dimensions, we also offer our customers the option of customizing these products as per their specific requirements. During the manufacturing process, our expert teams checks the quality of the products thus we ensure the superior products to our clients. The projects we undertake are completed within the promised time frame and our services are available at highly competitive prices.

From material to finished product, from design to produce, we control all steps, which is the guarantee of the quality and reliability.

Established in Taiwan, we, JAWBONE INDUSTRIAL CO., LTD., are a leading Manufacturer, Supplier and exporter of Injection Moulding Products, our technique and products include Plastic Injection Molding, Plastic Overmolding, 2 Shot Plastic Molding, Plastic Insert Molding, Plastic Mold, Plastic Mold Design, Plastic Molding Products, Assembly And Testing, Mechanical Design, and Secondary Processes, etc.. These are manufactured using the best quality raw materials at our ultramodern infrastructure facility. Our products guarantee optimum satisfaction of the end users.

We give you wide range of Injection Moulding Products as per your requirements; our material is made up of high quality material that is quality tested. Customers can avail this service from us in a given time at affordable rates. In addition to manufacturing these offered products in standard dimensions, we also offer our customers the option of customizing these products as per their specific requirements. During the manufacturing process, our expert teams checks the quality of the products thus we ensure the superior products to our clients. The projects we undertake are completed within the promised time frame and our services are available at highly competitive prices.

From material to finished product, from design to produce, we control all steps, which is the guarantee of the quality and reliability.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk