As a leading manufacturer, supplier and exporter in Taiwan, we specialize in the Plastic Insert Molding manufacturing. We have more than decade rich experience in the product's development, sales and installing, our products have obtained great reputation in domestic and oversea. Our company with high quality products, best services and good reputation, have won a great customers' support, and became more strength and powerful, the scale has been expanded and owned ourself manufactory.

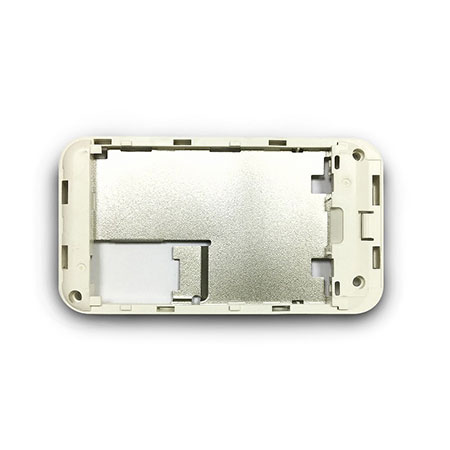

Plastic Insert Molding

Video Module

PISM-001

This product is molded with insert molding process.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: Plastic PC. All kinds of engineering plastic are available based on customers’ demands.

Color: White. Colors can be customized upon request.

Surface Finish: Textured. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

The causes of deformation or warping of plastic injection molded products

The deformation/warping of plastic injection molded products is a very difficult issue. It should be avoided mainly from the initial mold design and plastic material selection stage because the effect of adjusting molding parameters during production is very limited. Jawbone R&D team always provide suggestion and solution before kicking off the tooling. Customers can evaluate and select the most appropriate material thru the datasheet of material recommended.

Common causes of deformation are residual stress, cooling unevenly, improper demolding, sink deformation, and product structure deformation, etc.

Marine Equipment

PISM-002

This product is exclusively used on boats.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: Plastic PC + ABS. All kinds of engineering plastic are available based on customers’ demands.

Color: Black. Colors can be customized upon request.

Surface Finish: Textured. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Solutions to fix deformation or warping of plastic injection molded products

Residual stress: Deformation caused by molding pressure can be eliminated by reducing the pressure, increasing the temperature of the mold and material, or by annealing.

Cooling unevenly: If the cooling is uneven, deformation may occur. It can be solved by adjusting the mold temperature to the average temperature, setting different mold temperature and extending the cooling time according to the degree of warpage.

Improper demolding from the mold: The uneven ejection force causes deformation. It can be solved by increasing the draft angle, adding ejectors, or extending ejection area to optimize the ejection system.

Sink deformation: Sink deformation after molding is generally structural deformation. In such case, it may be necessary to modify the design. The most important thing is to make the overall material thickness even.

Product structure deformation: This is the most difficult problem. According to the product development stage and its requirement, there will be different solutions.

Before mold development: Use CAE software for deformation analysis in advance. It allows design changes to reduce deformation before the product development starts.

After mold development: Analyze the overall deformation trend according to the measurement data, and then proceed mold modification based on the data of different areas of mold.

Without change the mold structure and affect the product function, it is also possible to use auxiliary tool to modify the product.

IR Switch

PISM-003

This product is an IR switch used in surveillance camera. It is molded with insert molding process and has precision dimensions.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: PC + 30% GF. All kinds of engineering plastic are available based on customers’ demands.

Color: Black. Colors can be customized upon request.

Surface Finish: Polishing. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Core Technologies

Single shot molding

Double shot molding (two-shot molding)

Insert molding

Overmolding

Gas assisted injection molding

In-mold degating system

Variotherm molding

Molding Capabilities

Jawbone is equipped with a variety of injection molding machines, including Japanese TOYO fully electric injection molding machines and Victor Taichung injection molding machines. With the sufficient facility, Jawbone has the great ability to manufacture parts in vary sizes and with high complexity according to customers’ needs.

Single injection molding machine: From 50 to 850 tons.

Double injection molding machine: From 140 to 600 tons.

Single vertical injection molding machine: From 15 tons to 200 tons.

Other Equipment: Hot runner system, variotherm mold temperature control system, CNC automated degating system, frozen deflashing machine, etc.

Tea Maker Filter

PISM-004

This is a customized product which is molded with two-shot insert molding process.

Design: Build the mold according to customer's CAD; offer free mold trial samples.

Material: 3300 PREM/ Silicone. All kinds of engineering plastic are available based on customers’ demands.

Color: Black. Colors can be customized upon request.

Surface Finish: Textured. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Application of Diverse Plastic Resins

Various purpose of use in different condition: Antimicrobial plastics, flame retardant plastics, impact-resistant plastics, conductive plastics, weather-resistant plastics, foaming plastics, light guide plastics, etc.

Various engineering plastics for different products: ABS, PP, PE, PA, POM, PC, PMMA, PEI, TPU/TPE, PVC, PBT, LCP, etc.

Over-mold molding/ double injection molding with heterogeneous/bicolor materials: Transparent PC plus black PC, ABS plus TPR, ABS/PC plus TPU, etc.

Besides above, we can have inserts of different material insert-molded in plastic parts, the inserts include threaded inserts, iron mesh, silver pins, magnets, etc.

They are highly efficient and offer excellent service in the process of usage. We ensure that these

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk