Injection Molding Parts

JAWBONE INDUSTRIAL CO., LTD. is dedicated to making the best products for customers worldwide. We manufacture, supply and export Injection Molding Parts. We work closely with our clients in a wide spectrum of industries and for various application needs. In many years efforts, the company well developed and made much progress; meanwhile, confronting with the competition of market, we always stick to the management guideline of human-oriented, scientific management and excellent quality.

Injection Molding Parts

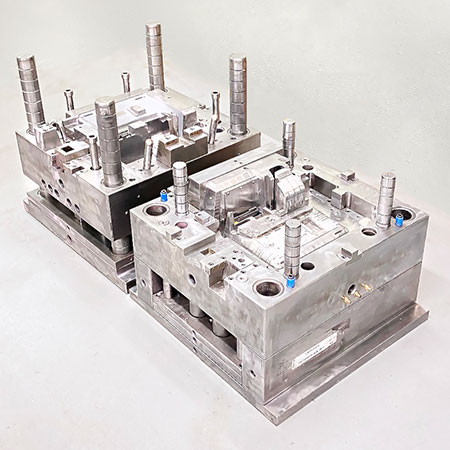

Model - PM-001

Cash Register Top Mold

PM-001

Three-plate mold with multi-gates and excellent design of conformal cooling.

Mold Capacities

Jawbone provides customers with a variety of mold building services and always discuss related contents with customers to make customers understand all issues and risk we may face before kicking off the too. Generally, process of molding includes plastic injection mold, blowing mold, thermoforming mold and metalwork mold.

The contents of mold types:

PM-001

Three-plate mold with multi-gates and excellent design of conformal cooling.

- Development: Mold design and mold injection are according to customers’ CAD, offer free mold trial samples.

- Material: PC+ABS. All kinds of engineering plastic are available based on customers’ demands.

- Surface Finish: Special texture. Both texture and polishing are available upon request.

- Color: Black and white. Colors can be customized upon request.

- Mold Base Steel: Select the most suitable P5 steel according to product demand.

- Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

- Demolding Mechanism: Provide solutions to expand life of mechanism actuation.

- Gate Type: Design the best runner system according to demands.

- Cooling System: Design the best conformal cooling channels according to structure of the product.

- Ejection System: Design the best ejection method according to structure of the product.

Mold Capacities

Jawbone provides customers with a variety of mold building services and always discuss related contents with customers to make customers understand all issues and risk we may face before kicking off the too. Generally, process of molding includes plastic injection mold, blowing mold, thermoforming mold and metalwork mold.

The contents of mold types:

- Standard two-plate mold, three-plate mold, and threaded mold

- Double injection mold

- Insert mold

- Hot runner mold

- Variotherm mold

- Gas assisted injection molding, and blowing molding

- Silicone rubber molding

- Die punch

Further the use of best quality raw materials and advanced machinery equipment allows us to have a better control over our production processes, enabling us to produce

Injection Molding Parts

that meet the international standards in terms of quality, durability & finish.Enquiry Now

Products List

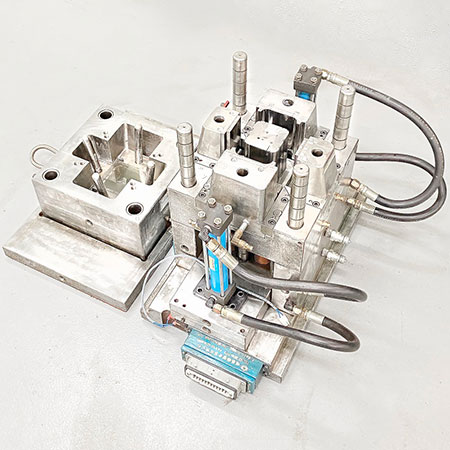

Surveillance Camera Top Mold

PM-002

RIM mold with hot runner design.

Development: Mold design and mold injection are according to customers’ CAD; offer free mold trial samples.

Material: PC+ABS. All kinds of engineering plastic are available based on customers’ demands.

Surface Finish: Polishing. Both texture and polishing are available upon request.

Color: Grey and orange. Colors can be customized upon request.

Mold Base Steel: Select the most suitable P5 steel according to demands.

Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Demolding Mechanism: Provide solutions. With precision hydraulic cylinder mechanism actuation.

Gate Type: Design the best runner system according to product demands.

Cooling System: Design the best conformal cooling channels according to structure of the product.

Ejection System: Design the best ejection method according to structure of the product.

Jawbone provides customer with the best choice for precision film materials.

Jawbone provides customers with the best products and services with our core technologies, equipment and capacities.

Core Technologies

Custom mold design and build

Continuous thin film coating

Continuous thin film printing

Stamping/die-cutting

Thin film lamination, etc.

Equipment & Capacities

Roll to roll thin film coating machines

Roll to roll automatic printing machines

C-type high-precision press punch

Thin film laminating machine with alignment function

Automated optical inspection (AOI)

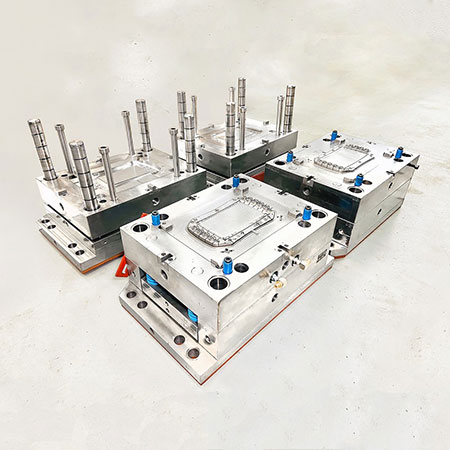

Marine GPS Mold

PM-003

Three-plate and double injection mold with multi-gates and excellent design of conformal cooling.

Development: Mold design and mold injection are according to customers’ CAD; offer free mold trial samples.

Material: PC+ABS/TPU. All kinds of engineering plastic are available based on customers’ demands.

Surface Finish: Texture. Both texture and polishing are available upon request.

Color: Red and white. Colors can be customized upon request.

Mold Base Steel: Select the most suitable S55C steel according to demands.

Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Demolding Mechanism: Provide solutions to expand life of mechanism actuation.

Gate Type: Design the best runner system according to product demands.

Cooling System: Design the best conformal cooling channels according to structure of the product.

Ejection System: Design the best ejection method according to structure of the product.

The Concept of Customer Services

Jawbone is well aware of how competitive this industry is. In order to retain every customer, we have always put customers in the top priority. We provide customers with good service to keep customers in a happy mood, so, at the same time, all team workers will be positively affected on both attitude and mood during the teamwork. As mentioned above, Jawbone is a company with concerted efforts, seamless cooperation, and internal harmony. All staffs participate in customers’ project with any barrier-free communication. We have perfect collaboration between each department.

Inquiry & Quote

Upon receipt of completing RFQ information, we will acknowledge receipt of RFQ immediately and respond to customers within 3-5 working days.

However, if the manufacturing processes are complicated or the quotation conditions are changed, the quote time will vary depending on the situation.

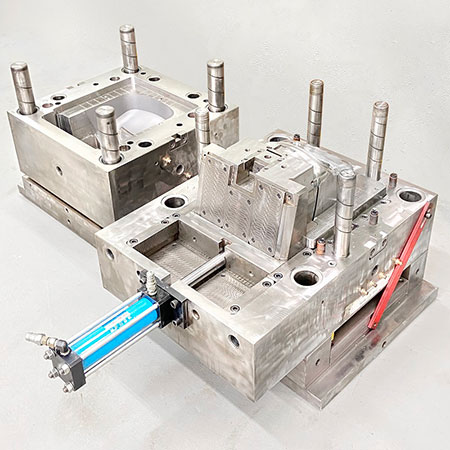

High Precise Particle Measuring Device Mold

PM-004

Three-plate and double injection mold with multi-gates and excellent design of conformal cooling.

Development: Mold design and mold injection are according to customers’ CAD; offer free mold trial samples.

Material: Makrolon 6557. All kinds of engineering plastic are available based on customers’ demands.

Surface Finish: Texture. Both texture and polishing are available upon request.

Color: Black. Colors can be customized upon request.

Mold Base Steel: Select the most suitable P5 steel according to demands.

Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Demolding Mechanism: Provide solutions to expand life of mechanism actuation.

Gate Type: Design the best runner system according to product demands.

Cooling System: Design the best conformal cooling channels according to structure of the product.

Ejection System: Design the best ejection method according to structure of the product.

Lead Time from Mold Building to Mass Production

Generally, it takes about 20-40 working days. If customers have special needs, we can also fully cooperate to reduce lead time.

The lead time for the different product development stages is as follows:

Building Mold:

It usually takes 20 to 30 working days. The actual mold building time may vary depending on the size of the product and the structure of the mold.

Trial Samples (T1 parts) ready for the customer approval:

After the mold building is completed, it may need testing and adjustment. Then, trial samples will be provided to the customer for approval, and it typically takes 5 working days.

Product Production:

After customer approves the part and places orders, the product can be shipped within 15-20 working days.

If any issues happen during the trial or production and requires mold modification, the final lead time of production will be changed according to the actual situation.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk