Mold Flow Analysis

JAWBONE INDUSTRIAL CO., LTD. is the leading manufacturer, supplier and exporter of Mold Flow Analysis in Taiwan. We use advanced technology to process them and assure our clients about the optimum performance. Our research team looks for innovative ideas, accepts challenges and works on evolving product-need based solutions. We offer these products at industry leading prices making them extremely popular among our clients. If you are interested in any of our products, please feel free to contact us.

Mold Flow Analysis

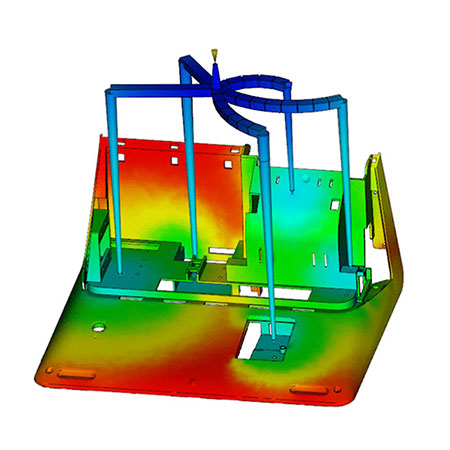

Model - PMD-003

Cash Register Mold Flow Analysis

PMD-003

Three-plate mold with multi-gates and excellent conformal cooling channels.

Quotation Conditions

Customer only has samples: Please let us know the application of the product, special quality requirements and other relevant product information, we will provide the corresponding quotation according to the information you provide. Jawbone has 3D Scanner that can do reverse engineering based on a legal ownership of the sample.

Customer only has a rough estimated dimension of the product: The product structure, precision, appearance, process, etc. will affect manufacturing costs, so in the absence of sufficient information, we can only give rough estimates based on the information you provide. After the design details are confirmed or the file/drawing is provided, we will provide you with a more precise quotation.

PMD-003

Three-plate mold with multi-gates and excellent conformal cooling channels.

- Development: Mold design and mold injection are according to customers’ CAD; offer free mold trial samples.

- Material: ABS. All kinds of engineering plastic are available based on customers’ demands.

- Surface Finish: Texture. Both texture and polishing are available upon request.

- Color: Black and white. Colors can be customized upon request.

- Mold Base Steel: Select the most proper steel according to demands.

- Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

- Demolding Mechanism: Provide solutions to expand life of mechanism actuation.

- Gate Type: Design the best runner system according to demands.

- Cooling System: Design the best conformal cooling channels according to structure of the product.

- Ejection System: Design the best ejection method according to structure of the product.

Quotation Conditions

Customer only has samples: Please let us know the application of the product, special quality requirements and other relevant product information, we will provide the corresponding quotation according to the information you provide. Jawbone has 3D Scanner that can do reverse engineering based on a legal ownership of the sample.

Customer only has a rough estimated dimension of the product: The product structure, precision, appearance, process, etc. will affect manufacturing costs, so in the absence of sufficient information, we can only give rough estimates based on the information you provide. After the design details are confirmed or the file/drawing is provided, we will provide you with a more precise quotation.

Our greatest asset is our committed employees that provide excellent

Mold Flow Analysis

. Our experienced, friendly personnel are trained to respond promptly to your questions and fully explain design requirements.Enquiry Now

Products List

Lollipop Baby Surveillance Camera

PMD-001

Three-plate mold with multi-gates and excellent conformal cooling channels.

Development: Mold design and mold injection are according to customers’ CAD; offer free mold trial samples.

Material: PC+ABS. All kinds of engineering plastic are available based on customers’ demands.

Surface Finish: Texture. Both texture and polishing are available upon request.

Color: Blue, pink and white. Colors can be customized upon request.

Mold Base Steel: Select the most suitable S55C steel according to demands.

Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Demolding Mechanism: Provide solutions. With precision hydraulic cylinder mechanism actuation.

Gate Type: Design the best runner system according to product demands.

Cooling System: Design the best conformal cooling channels according to structure of the product.

Ejection System: Design the best ejection method according to structure of the product.

High Precision Machining and Manufacturing

Diversified Metal Processing Services

In response to industry development and customer’s demand, Jawbone keeps expanding our manufacturing services. We leverage manufacturing experience combining with processing expertise to supply high-precision parts, such as machined parts, stamped parts, die-casted parts, and aluminum extrusion components.

Services about Metal Parts

Manufacturing Process Consulting

Mold Making

Metal Parts Processing

Surface Finishing

Assistance in Metal Material Selection

Metal Material We Use: Stainless steel, aluminum alloy, copper alloy, zinc alloy, etc. We could manufacture and do the processing for various kinds of metal parts.

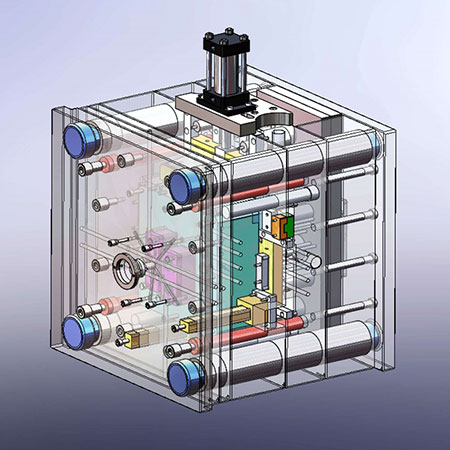

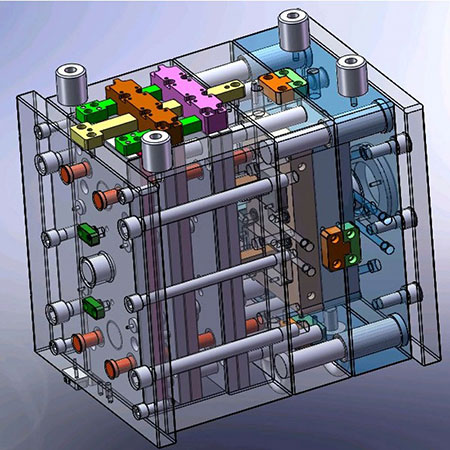

Medical Monitor

PMD-002

Three-plate mold with multi-gates and excellent conformal cooling channels.

Development: Mold design and mold injection are according to customers’ CAD; offer free mold trial samples.

Material: PC+ABS. All kinds of engineering plastic are available based on customers’ demands.

Surface Finish: Texture. Both texture and polishing are available upon request.

Color: Blue and white. Colors can be customized upon request.

Mold Base Steel: Select the most suitable S55C steel according to demands.

Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Demolding Mechanism: Provide solutions to expand life of mechanism actuation.

Gate Type: Design the best runner system according to product demands.

Cooling System: Design the best conformal cooling channels according to structure of the product.

Ejection System: Design the best ejection method according to structure of the product.

Provide Comprehensive Secondary Processing for Your Choice

Promote Value of Product

Satisfy All Your Needs in Our One-stop Shop!

Manufacturing of mechanical parts is inseparable from the post-process processing. A completed product usually comes with mechanical part and secondary processing, such us painting, printing, coating, electroplating, etc. In addition to manufacturing metal and plastic parts, Jawbone provides services of post-processing. Our goal is to meet various customer expectations in manufacturing at one-stop. Customers just simply face the only window, Jawbone, who will be in charge of communicating and supervising all development and process for customers. Jawbone always helps customer to save time and money.

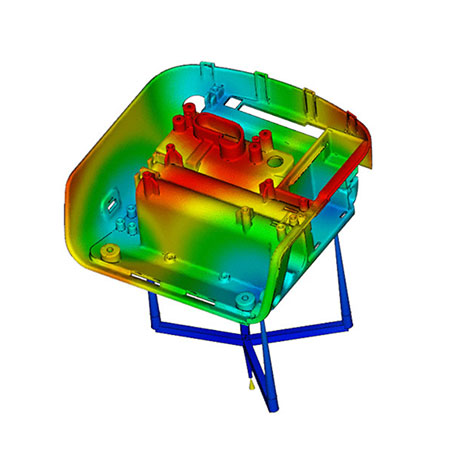

Particle Measuring Device Mold Flow Analysis

PMD-004

Three-plate mold with multi-gates and excellent conformal cooling channels.

Development: Mold design and mold injection are according to customers’ CAD; offer free mold trial samples.

Material: Makrolon 6557. All kinds of engineering plastic are available based on customers’ demands.

Surface Finish: Texture. Both texture and polishing are available upon request.

Color: Black. Colors can be customized upon request.

Mold Base Steel: Select the most proper steel according to demands.

Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Demolding Mechanism: Provide solutions to expand life of mechanism actuation.

Gate Type: Design the best runner system according to demands.

Cooling System: Design the best conformal cooling channels according to structure of the product.

Ejection System: Design the best ejection method according to structure of the product.

Jawbone provides early stage small-volume production/trial production services:

Before formally mass production, we can make a small batch of trial production/pilot run for customers to verify the relevant quality requirements and process stability.

Plastic injection products be made in small quantity, and the minimum order for production is as following:

In response to the current demand in the market which always requires diverse products in a small quantity, Jawbone provides customers with a minimum order of 200 pcs per item. However, the small-quantity order will result in relatively higher production cost. Jawbone will provide customers the unit price of parts with different MOQ so they can make the most cost-effective choice for their purchasing order.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk