Portable GPS Device

As a leading manufacturer, supplier and exporter in Taiwan, we specialize in the Portable GPS Device manufacturing. We have more than decade rich experience in the product's development, sales and installing, our products have obtained great reputation in domestic and oversea. Our company with high quality products, best services and good reputation, have won a great customers' support, and became more strength and powerful, the scale has been expanded and owned ourself manufactory.

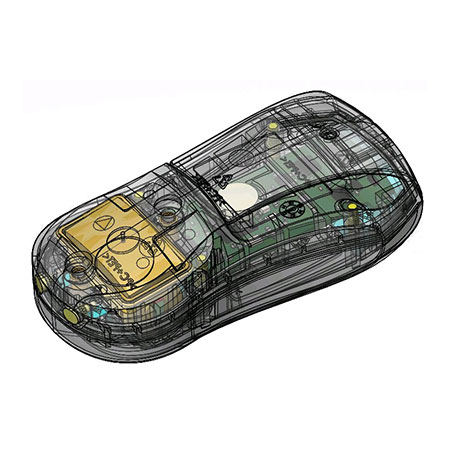

Portable GPS Device

Model - MD-003

Portable GPS Device

MD-003

Apply SolidWorks to design. Provide 2D&3D CAD and manufacture samples.

Mold Building Equipment

Jawbone's mold building equipment includes:

CNC Milling Machine, High-Speed Milling Machine, Milling Machine, Grinder, ZNC EDM Machine, EDM Machine, NC EDM Machine, Lathe Machine, Shearing Machine, Height Gauges, Linear Height Gauges, Form grinder, Ejector pin cutting off machine, and Cutting off machine.

Assembly Instrument

Jawbone's assembly Instrument includes:

Glue Dispenser (Manual & Automatic), Ultrasonic Welding Machine, Hand Press Machine, Soldering Machine, Soldering Ironing, Electrical Screwdriver, Power Supply, Drilling Machine, Semi Auto Filling Machine, Air Press Machine (Handheld), Heat staking Machine (S, M, L), Sealing Machine, Air Press Machine, Assembly Line Conveyor, and Self-Contained Plastics Assembly Ultrasonic Welder.

MD-003

Apply SolidWorks to design. Provide 2D&3D CAD and manufacture samples.

- Design: Build the mold according to customer's CAD, offering free mold trial samples.

- Material: ABS. All kinds of engineering plastic are available based on customers’ demands.

- Color: Red and white. Colors can be customized upon request.

- Surface Finish: Special texture. Both polishing and texture are available upon request.

- Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

- Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

- Country of Origin: Taiwan

Mold Building Equipment

Jawbone's mold building equipment includes:

CNC Milling Machine, High-Speed Milling Machine, Milling Machine, Grinder, ZNC EDM Machine, EDM Machine, NC EDM Machine, Lathe Machine, Shearing Machine, Height Gauges, Linear Height Gauges, Form grinder, Ejector pin cutting off machine, and Cutting off machine.

Assembly Instrument

Jawbone's assembly Instrument includes:

Glue Dispenser (Manual & Automatic), Ultrasonic Welding Machine, Hand Press Machine, Soldering Machine, Soldering Ironing, Electrical Screwdriver, Power Supply, Drilling Machine, Semi Auto Filling Machine, Air Press Machine (Handheld), Heat staking Machine (S, M, L), Sealing Machine, Air Press Machine, Assembly Line Conveyor, and Self-Contained Plastics Assembly Ultrasonic Welder.

Equipped with high end facilities and a

Portable GPS Device

of highly qualified and experience professional the company thrives to deliver the best of quality at the most affordable cost. Going forward, we pledge to give our best in terms of value and customer satisfaction.Enquiry Now

Products List

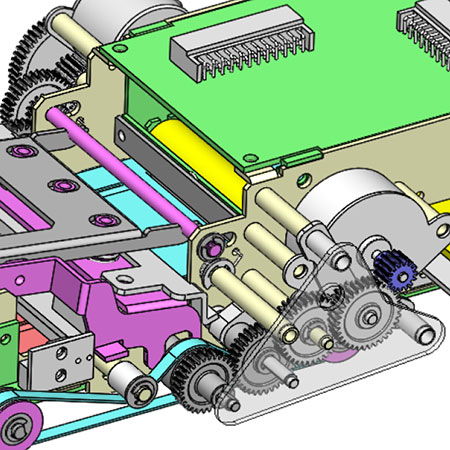

Printer Gear Driving Module

MD-001

Apply SolidWorks to design. Provide 2D&3D CAD and manufacture samples.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: PC+ABS. All kinds of engineering plastic are available based on customers’ demands.

Color: White. Colors can be customized upon request.

Surface Finish: Special texture. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Solutions for Plastic Injection Molding

Low volume, High variety, Superior quality

Jawbone applies various engineering materials, combining with CAE mold flow review to produce parts. We allow customer’s small amount demand of diversified production.

Jawbone has abundant experience in plastic injection molding section and expertise in all kinds of precision plastic injection molding. Through CAE mold flow analysis and with many years of production experience, we effectively solve various issues of injection molding for customers. We always provide the best solution before kicking off the tooling and provide high-quality products for customers. All processes are to avoid modifying tooling and causing tooling cost to be increased.

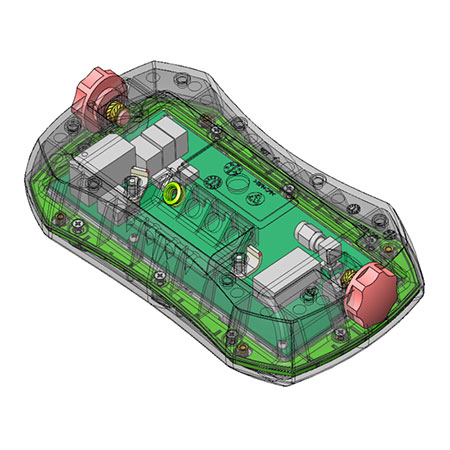

GPS Host Device

MD-002

Apply SolidWorks to design. Provide 2D&3D CAD and manufacture samples.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: PC+ABS. All kinds of engineering plastic are available based on customers’ demands.

Color: Grey. Colors can be customized upon request.

Surface Finish: Texture. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Injection Molding Equipment

Jawbone's injection molding equipment includes:

Single Horizontal Injection Molding Machine, Single Vertical Injection Molding Machine, Double Injection Molding Machine, Temperature Controller, Vision System for Mold Protection, Instant Cold/hot Mold Temperature Control Unit, and Dehumidifying Dryers Equipment

Testing/Inspection Instrument

Jawbone has labs and inspection room which are with CNC 2.5D Image Processing Measuring Instrument, 3D Coordinate Measuring Machine, Automated Vision System, Blue Light 3D Scanner CMM, Colorimeter, Microscope, Handheld XRF Analyzer, Temperature & Humidity test chamber, Tensile Testing Machine, Abrasion Resistant Tester, and Moisture Analyzers.

With varied equipment for production and precise instruments for inspection, Jawbone has confident to approach customer’s any request.

Infant Car Seat

MD-004

Apply SolidWorks to design. Provide 2D&3D CAD and manufacture samples.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: PC+ABS. All kinds of engineering plastic are available based on customers’ demands.

Color: Dark Blue. Colors can be customized upon request.

Surface Finish: Texture. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Developing New product is risky and mold cost is high.

Following “low-cost methods” can help validate your design:

Before kicking off the mold, you can choose some prototype option first according to the product requirements to validate your product design.

The prototype options, including:

CNC prototyping

Silicone prototyping

3D Printing prototyping

When the product is with short life cycle and small quantity demand, the following method can help to reduce the cost other than production mold:

You can choose to make a soft mold, which uses mild steel material.

Mold cost is closely related to steel material. The lower the hardness of steel, the lower the cost of the mold. The lifetime cycle of soft mold is short, and the volume can be produced is also small.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk