Two Shot Molding

JAWBONE INDUSTRIAL CO., LTD. is leading manufacturer, supplier and exporter of Two Shot Molding. With a factory in Taiwan. Our expertise allows us to offer a comprehensive range of, which is developed in tandem with the international quality standards. During the manufacturing process, our expert teams checks the quality of the products thus we ensure the superior products to our clients. Our services are highly appreciated by our clients for timely services and market leading prices. If you are interested in any styles of our products, please feel free to contact us.

Two Shot Molding

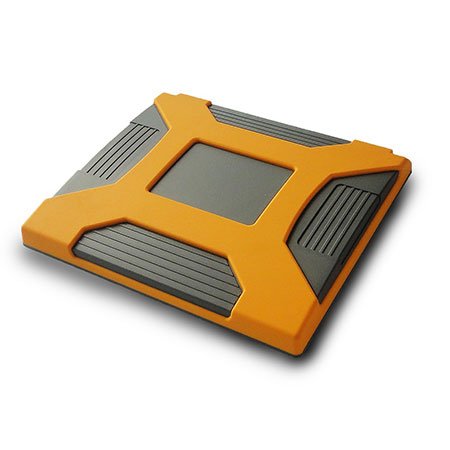

Model - DSPM-002

Outdoor Ultrasonic Device

DSPM-002

This product is specially used in outdoor places like farms and ranches. It is with anti-collision and water-repellent features which is able to withstand trucks or other heavy things running over.

With CAE analysis, we reduce development risk.

Jawbone has capability of precision mold built and precision processing equipment. Through mold flow analysis and design review by skilled engineers before making the mold, we find the best solution for product molding. Also, Jawbone strengthens the structure and quality of mold to reduce the need of mold modification and to minimize development risk. We provide customers with timely and cost-effective mold development services.

DSPM-002

This product is specially used in outdoor places like farms and ranches. It is with anti-collision and water-repellent features which is able to withstand trucks or other heavy things running over.

- Design: Build the mold according to customer's CAD, offering free mold trial samples.

- Material: Plastic PC + PBT/TPE. All kinds of engineering plastic are available based on customers’ demands.

- Color: Orange and grey. Colors can be customized upon request.

- Surface Finish: Textured. Both polishing and texture are available upon request.

- Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

- Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

- Country of Origin: Taiwan

With CAE analysis, we reduce development risk.

Jawbone has capability of precision mold built and precision processing equipment. Through mold flow analysis and design review by skilled engineers before making the mold, we find the best solution for product molding. Also, Jawbone strengthens the structure and quality of mold to reduce the need of mold modification and to minimize development risk. We provide customers with timely and cost-effective mold development services.

We specialize in fabricating a wide range of

Two Shot Molding

. Ours products are finished to perfection by our expert team of designers and are subject to customization as per the demands of our clients.Enquiry Now

Products List

Industrial Tablet

DSPM-001

This product is molded thru double injection molding process which looks fashionable and is drop-proof function. It is equipped with a special charging stand that makes the product easier to use.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: Plastic PC + ABS/TPSiV. All kinds of engineering plastic are available based on customers’ demands.

Color: White and green. Colors can be customized upon request.

Surface Finish: Textured. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

A Perfect Balance Between Design and Manufacturing

We make your idea not just an imagination anymore.

We work hard to make your ideas real. We provide customers with complete custom product services, assist customers in solving various issues encountered during development, and maintain good and continuous communication with customers through designated project managers.

Marine GPS

DSPM-003

This product is a marine GPS with IPX7 waterproof rating. It is molded with double injection molding process and used by ships or offshore platforms.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: PC+PET/TPE. All kinds of engineering plastic are available based on customers’ demands.

Color: Orange and white. Colors can be customized upon request.

Surface Finish: Textured. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Upholding the faith of continuous innovation and the pursuit of excellence, Jawbone is also committed to the development and manufacturing of PET film processing products. Our skilled engineering team works collaboratively from the development of materials to product design verification and mass production to provide customers with complete application solutions.

In addition, Jawbone also has sequent automated production equipment of each process with clean and dust-free manufacturing environment. We can provide customers with a large quantity of high-precision, high-quality processed film materials, such as test strips for IVD medical devices.

Tree-shaped Decorations

DSPM-004

This is a customized tree-shaped decorated product molded with double injection molding process.

Design: Build the mold according to customer's CAD, offering free mold trial samples.

Material: PC+ABS/ABS. All kinds of engineering plastic are available based on customers’ demands.

Color: Green and white. Colors can be customized upon request.

Surface Finish: Textured. Both polishing and texture are available upon request.

Mold: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

Quality: Certified to ISO-9001, ISO-14001, UL, RoHS, and REACH regulations.

Country of Origin: Taiwan

Plastic Raw Material Types

Plastic polymers can be divided into two main categories:

Thermosoft plastic: Plastics can soften and be reshaped when heated at a certain temperature. The curing process is completely reversible. It is recyclable and reusable, but with poor heat resistance. According to the function, it is classified as general plastics, engineering plastics, elastomers. For example, PET bottle, acrylic, etc.

Thermosetting plastics: Plastics will become irreversibly rigid after heated which is not easy to recycle. It cannot be remolded or reheated after molding but is more heat resistant and weather resistant than thermoplastics. For example, tires, dishes, melamine tableware, etc.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk